Recondensing Magnet Systems with 4.2K Cryocoolers

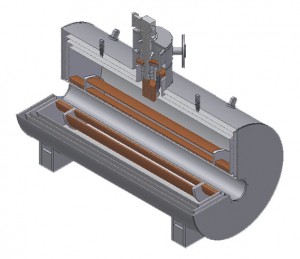

Recondensing superconducting magnet systems use a 4.2K cryocooler to recondense liquid helium boiloff during static (persistent mode) operation. Depending upon the particular system design and the customer’s planned use schedule, the 4.2K cryocooler can completely stop liquid helium boiloff and result in a zero loss system.

Recondensing systems are usually designed with a small amount of stored liquid helium. This results in a more compact design as compared to traditional superconducting magnet systems.

In all recondensing superconducting magnet systems, Cryomagnetics proprietary high temperature superconductor current leads are installed to minimize liquid helium usage. Cryomagnetics’ high temperature current leads are proven performers and have been used in many superconducting magnet systems over the years.

Always designed with safety in mind, all recondensing systems are designed to ASME code and manufactured in Cryomagnetics’ facility under strict quality procedures.

All recondensing systems are equipped with Cryomagnetics exclusive HRC-110 Helium Reliquefier Control System.

The HRC-110 is designed to control liquefying rate by constantly monitoring pressure in the superconducting magnet system’s helium chamber. Positive pressure will always be present within the helium chamber, thereby reducing the risk of ice formation. Features a digital display and easy integration in existing superconducting magnet systems.

As with traditional liquid helium based superconducting magnet systems, recondensing systems are available with a variety of thermal radiation shielding options. Intermediate thermal radiation shielding using liquid nitrogen is available, or designs with multiple thermal radiation shields without the use of liquid nitrogen are available. Experiments that require elevated temperatures in the room temperature bore can be accommodated as well as other special conditions.

Another very important factor to consider when deciding between a liquid cryogen free or a liquid helium based system is how the design addresses power outages and superconducting magnet quenches.

In the event of a power outage or cryocooler failure in a recondensing system, the liquid helium buffer will allow enough time for a safe discharge of the superconducting magnet without quench.

In a liquid cryogen free only system, the time between loss of cooling power and temperature rise above 4.2K is a matter of minutes, not allowing enough time for the safe discharge of the superconducting magnet.

The recondensing system can be viewed as having the best of both liquid cryogen free and liquid helium based systems—liquid helium costs are minimized, systems can be made smaller, and they have the ability to tolerant power faults without superconducting magnet quenches.

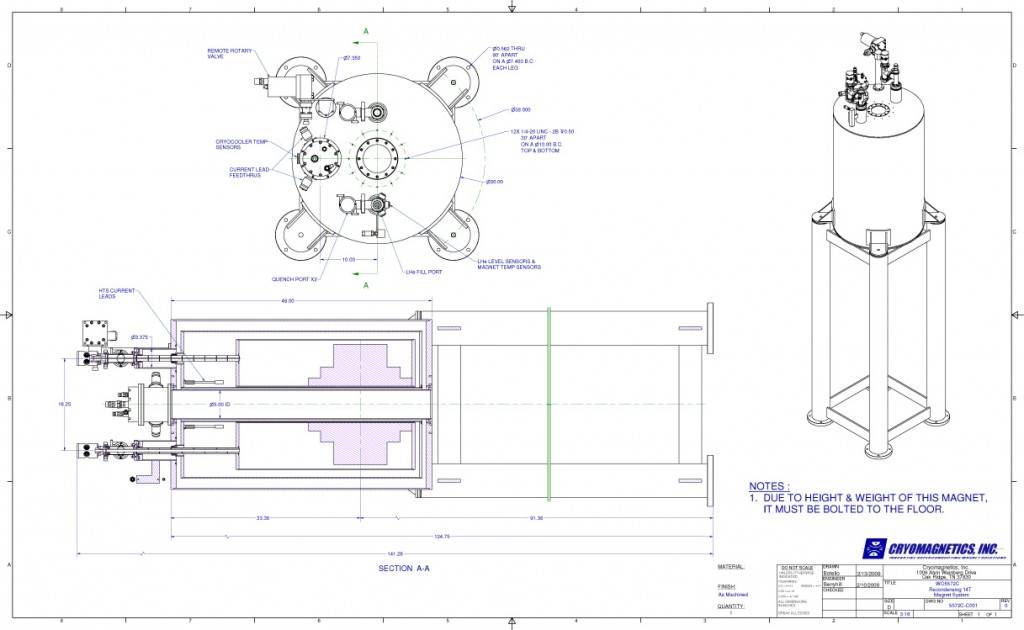

Example 14T Recondensing System Quotation

Use this example to help define your specific needs…

Superconducting Magnet

Custom designed solenoid configuration with a 14 Tesla central field (4.2K) and high resistance, persistent mode switch installed.

Fully protected against damage due to quench.

One (1) ruthenium oxide temperature installed to monitor temperature during operation.

Recondensing Dewar

4.2K pulse-tube or Gifford-McMahon cryocooler to reduce or stop liquid helium boil off.

Vertical room temperature bore.

Welded aluminum construction.

Room temperature bore diameter: 127mm (5.00 inches) I.D.

Liquid helium boil off rate: Zero in static mode

No liquid nitrogen required.

Redundant liquid helium level sensors installed.

LN2 precool/removal tube.

Safety sealed quench relief system.

Vacuum space safety drop out plate.

15 foot long instrumentation cabling.

One (1) ruthenium oxide temperature installed on the thermal radiation shield to monitor temperature during operation.

Cryocooler Specifications

1.0W @ 4.2K pulse-tube or Gifford-McMahon cryocooler.

Water cooled compressor.

One (1) ruthenium oxide temperature installed on the 1st stage of the cold head to monitor temperature during operation.

One (1) ruthenium oxide temperature sensor installed on the 2nd stage of the cold head to monitor temperature during operation.

The compressor service interval is 15,000 hours. This is a simple adsorber replacement.

Model LM-510 Liquid Cryogen Monitor

Set up as a single channel instrument to monitor liquid helium levels.

CE-Marked.

240 x 400 TFT LCD display.

Simple, intuitive user interface.

Sample and hold operation. (1 minute to 99 hours settability)

Manual update or continuous operation.

Sensor de-ice cycle. (LHe only)

Sensor calibration via front panel menu.

Can drive sensors up to 200cm active.

High and low setpoint control output.

USB Interface.

IEEE-488 Interface.

Ethernet Interface.

LabVIEW® drivers available.

See photo and further description here

Model TM-612 and 614 Temperature Monitor

Used to monitor cryocooler, shield, and superconducting magnet temperatures.

Set up as a dual channel instrument (Option 3 installed) to simultaneously monitor two temperature sensors.

CE-Marked.

Bright, two line vacuum fluorescent display.

RS-232 computer interface.

Option 2: IEEE-488.2 Computer Interface installed.

Temperature displayed in Kelvin, Celsius, Fahrenheit, or expressed as a resistance.

Audible alarm (can be silenced).

Control output with high and low setpoints.

Simple keypad with good tactile response.

19” Rack Mountable Cabinet

LabVIEW® drivers available at no extra charge.

Model 4G-100 Integrated Superconducting Magnet Power System

The Model 4G-100 is a single output model with output current up to ± 100 amperes at 800 watts (± 10 volts up to 80 amperes, ± 8 volts at 100 amperes).

CE-Marked

4-quadrant, true bipolar systems featuring smooth sweeps through zero.

Automatic quench detection and protection.

A full color, backlit TFT liquid crystal display clearly indicates output current, voltage, limit settings, and system status.

Current settability of 0.1 milliamps

Five (5) programmable sweep rate ranges.

Persistent switch heater power supply.

15 foot length output cables.

USB, IEEE-488.2, and Ethernet computer interfaces standard.

Safety interlocks for persistent switch enable/disable and changing of important magnet parameters and limits.

Visual confirmation of current present in leads will alert users to be mindful of safety when operating the power supply, even if line power is off.

Instrumentation Cabinet

Industry-standard 19” inside width.

Prewired to house all instrumentation quoted.

Please click on the following links for more information:

Please Contact Cryomagnetics at sales@cryomagnetics.com or your local Sales Representative for a price quotation.

Cryomagnetics offers online ordering for electronic instrumentation:

- 4G Bipolar Power Supplies

- Liquid Cryogen Level Monitoring & Control

- Temperature Monitoring & Control

- Magnetic Field Monitoring & Control